Hi All,

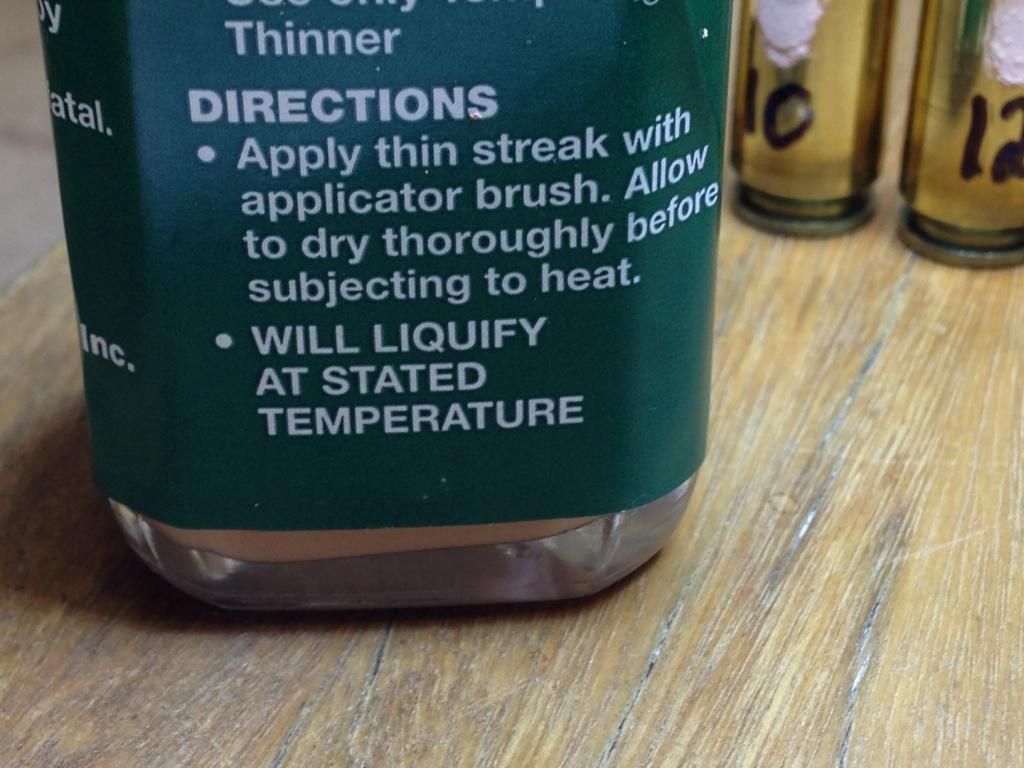

I bought some 700 deg F Tempilaq and had a play tonight. Thought I'd post up some pics incase anyones interested.

I'm using BBQ gas, a burnzomatic torch and old .284 Lapua brass..

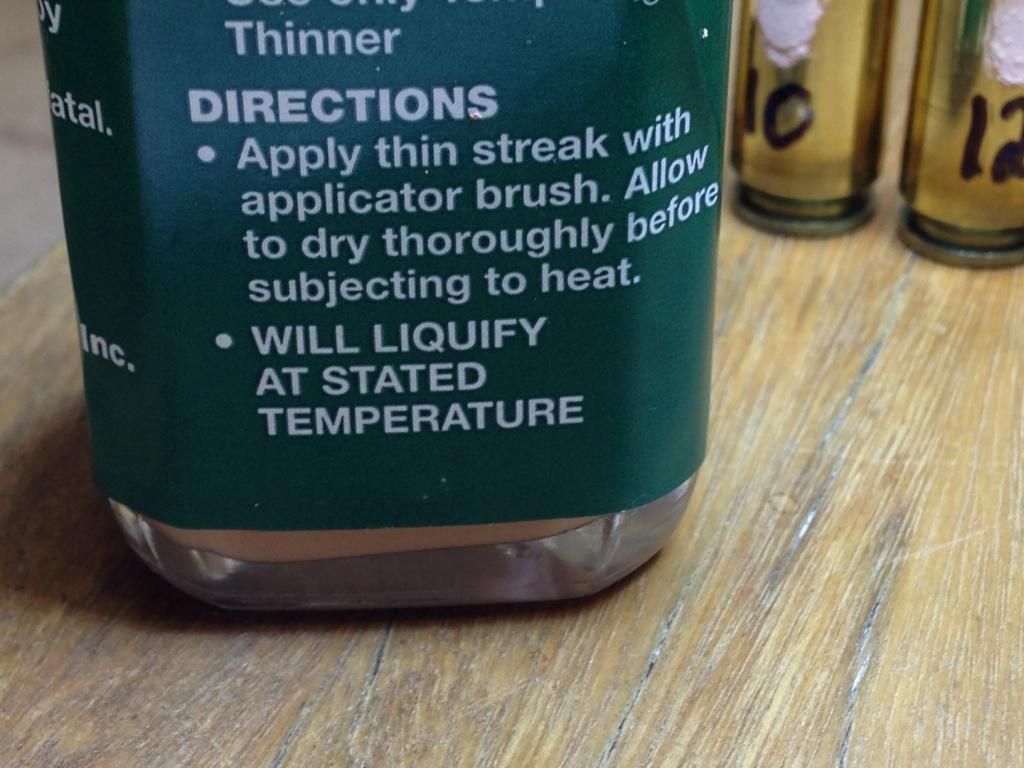

I've written my annealing time in seconds 1 1000, 2 1000, 3 1000 etc at the bottom of each case.

I went from under cooked to overcooked to see the extremes. All cases were air cooled.

Note that the specified temp is reached when the Tempilaq liquifies.

Looking at the pics you can see that 4 and 6 still show clear paint in the neck..... under done

8 and 10 show charred paint in the neck but the Tempilaq still has body............ getting there

12 is the point that the Tempilaq liquifies inside the neck.

Interesting to see that even overcooked with BBQ gas, 16 and 18 still havent annealed the bulk of the body or anywhere near the head.