Heres a thought that may be absolute B.S, but it's occurred to me quite a few times.

Whenever I shoot, afterwards, I like to have a sticky beak at the carbon pattern on the muzzle.

I've noticed that when the gun/loads shooting really well, theres a very clear and precise pattern/star/snowflake on the crown and normally quite large.

In the past when load testing or when loads have needed a tweak due to batch changes in powder, etc, I think I've noticed that poor loads don't produce clear and difinitive patterns on the crown and sometimes, only small ones.

Has any one else seen this or am I just looking to much in to it?

Is there a relationship between a good tune and crown carbon patterns?

The forums a bit quiet so why not throw it out there..........

Crown carbon patterns?

Moderator: Mod

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

-

DaveMc

- Posts: 1453

- Joined: Mon Aug 22, 2011 6:33 pm

I don't think I would like to really comment either way but maybe make a possible link with the "optimum barrel time" theories of Chris Long again. There is a train of thought that the barrel muzzle diameter may be enlarged by the "P" wave generated at certain points. Perhaps this acts like a bad crown??

??????????????????????????????????

??????????????????????????????????

-

Brad Y

- Posts: 2181

- Joined: Fri Jun 26, 2009 8:21 pm

Quite possible, I know from recent load development my 7mm was shooting ok and had a slight flash mark going on. Once I found a load that shot a 5 shot group into 1/4MOA elevation, I noticed that there was a very distinct and uniform pattern around the outside of the crown. Come to think of it, never have I seen a gun not shoot well and get up and not see a nice carbon flash mark on the outside of the crown. Alot of people get up with a big grin on thier face and check how nice its flashing... Definitely a potential link, somebody got a few barrels and some components they want to test it with and report back

-

shooter mcreid

- Posts: 322

- Joined: Sat Mar 01, 2014 5:26 pm

- Location: Ipswich

-

williada

- Posts: 969

- Joined: Wed Jul 22, 2009 12:37 am

It is so important that the crown is cut at the minimum diameter and perpendicular to the bore. Most often the culprit is a belling caused by the bore lap after manufacture as it is stopped and drawn back. On cut barrels the problem can be variable land height. I never noticed the buttoned barrels exhibiting this fault in production except that induced by the lap. All good gunsmiths cut the barrel blank back to the minimum bore diameter.

An even snowflake pattern as you guys are calling it does reveal a good muzzle. But too much black could indicate an inefficient powder burn. The picture of the barrel is not indicative of an oval bore as usually the land height in an oval bore of the snowflake is still even.

If you grind the crown with a ball bearing or a round copper lap copper lap, the crown will always be perpendicular to the bore. You don't need a lathe, you can use a hand drill, but you must rotate the vertical handle in a wide and varying arc so as not to promote uneven ware on the round lap and so uneven grind on the crown.

David.

An even snowflake pattern as you guys are calling it does reveal a good muzzle. But too much black could indicate an inefficient powder burn. The picture of the barrel is not indicative of an oval bore as usually the land height in an oval bore of the snowflake is still even.

If you grind the crown with a ball bearing or a round copper lap copper lap, the crown will always be perpendicular to the bore. You don't need a lathe, you can use a hand drill, but you must rotate the vertical handle in a wide and varying arc so as not to promote uneven ware on the round lap and so uneven grind on the crown.

David.

-

DenisA

- Posts: 1526

- Joined: Wed Nov 09, 2011 7:00 pm

- Location: Sunshine Coast, QLD

A good test would be reverse load test a known good load. Maybe 4, 5 shot groups with say .3 g intervals, taking a photo of the crown and wiping it clean after each group. The pics could be compared with the groups.

The barrel would have to be fouled first.

I don't know that its time well spent because even if it did prove to be true, what would be the advantage of the info to the shooter.

The barrel would have to be fouled first.

I don't know that its time well spent because even if it did prove to be true, what would be the advantage of the info to the shooter.

-

Frank Green

- Posts: 352

- Joined: Wed May 28, 2014 11:48 pm

williada wrote:It is so important that the crown is cut at the minimum diameter and perpendicular to the bore. Most often the culprit is a belling caused by the bore lap after manufacture as it is stopped and drawn back. On cut barrels the problem can be variable land height. I never noticed the buttoned barrels exhibiting this fault in production except that induced by the lap. All good gunsmiths cut the barrel blank back to the minimum bore diameter.

An even snowflake pattern as you guys are calling it does reveal a good muzzle. But too much black could indicate an inefficient powder burn. The picture of the barrel is not indicative of an oval bore as usually the land height in an oval bore of the snowflake is still even.

If you grind the crown with a ball bearing or a round copper lap copper lap, the crown will always be perpendicular to the bore. You don't need a lathe, you can use a hand drill, but you must rotate the vertical handle in a wide and varying arc so as not to promote uneven ware on the round lap and so uneven grind on the crown.

David.

We recommend to cut off 1" and crown the muzzle to cover any tool runout/lapping, belling etc....

With that being said though I've seen button rifled barrels that were finished lapped that had belling etc....to the bores as well.

Also button barrels due to the stress induced into the steel when they are button rifled you should check the bore before and after crowning the muzzle. Any stress in this area and depending on the size (o.d. of the barrel) when you cut and crown it you can relieve the stress and the bore could open up on you.

Later, Frank

Bartlein Barrels

-

Frank Green

- Posts: 352

- Joined: Wed May 28, 2014 11:48 pm

-

Brad Y

- Posts: 2181

- Joined: Fri Jun 26, 2009 8:21 pm

Well here is the start of some evidence... this is what my crown looked like after a 60.7 at 800m. One of those wide 6's was a sighter. On a positive note, Im finally happy with how this gun is working! Thats tight enough for me considering it was a switchy little tail wind! My hot 260 didnt hold that high an X count when I screwed it on later in the morning. Time to stop load developent!

Krieger 5r 284 shehane and 180vld's

Krieger 5r 284 shehane and 180vld's

-

plumbs7

- Posts: 1124

- Joined: Wed Feb 12, 2014 7:32 am

- Location: Dalby/ Tara Rifle Club

Well , since we are showing groups then . On Saturday just gone , went to a cattle farm at Cadarga to do my last training session before the Nats .

This is the rem with Lilya 28" barrel and 155 bergers , thrown with the charge master .

The gong was set up at 1030 m . Upper group was 9.7mills elevation. Lower group was 9.6 mills .

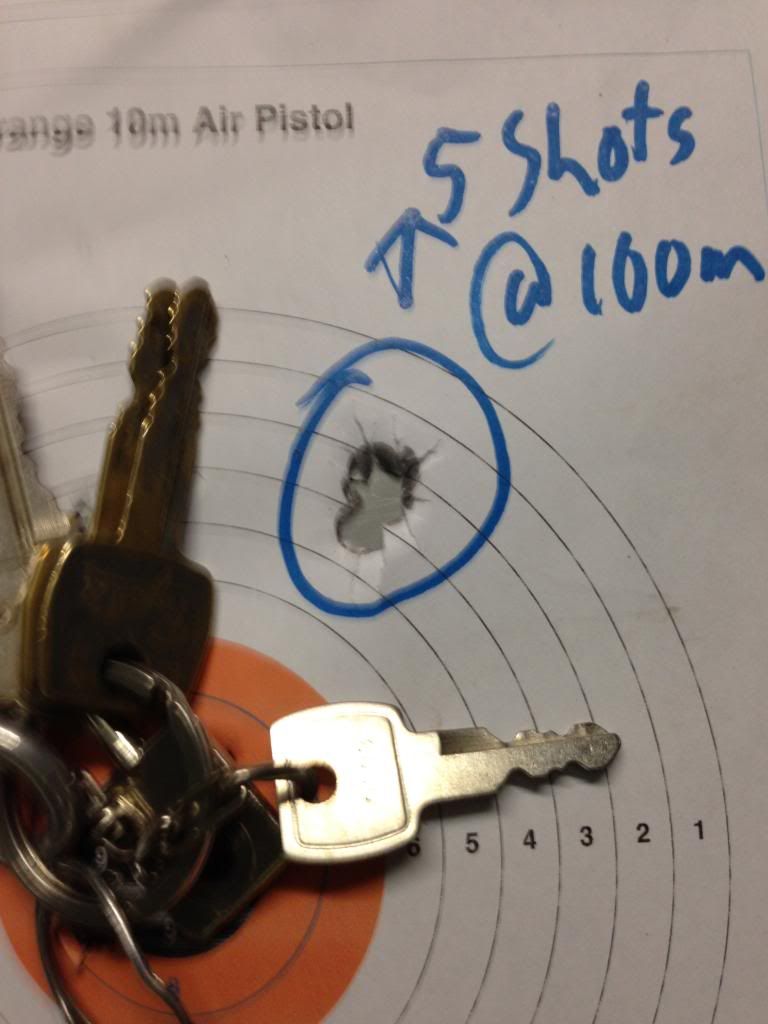

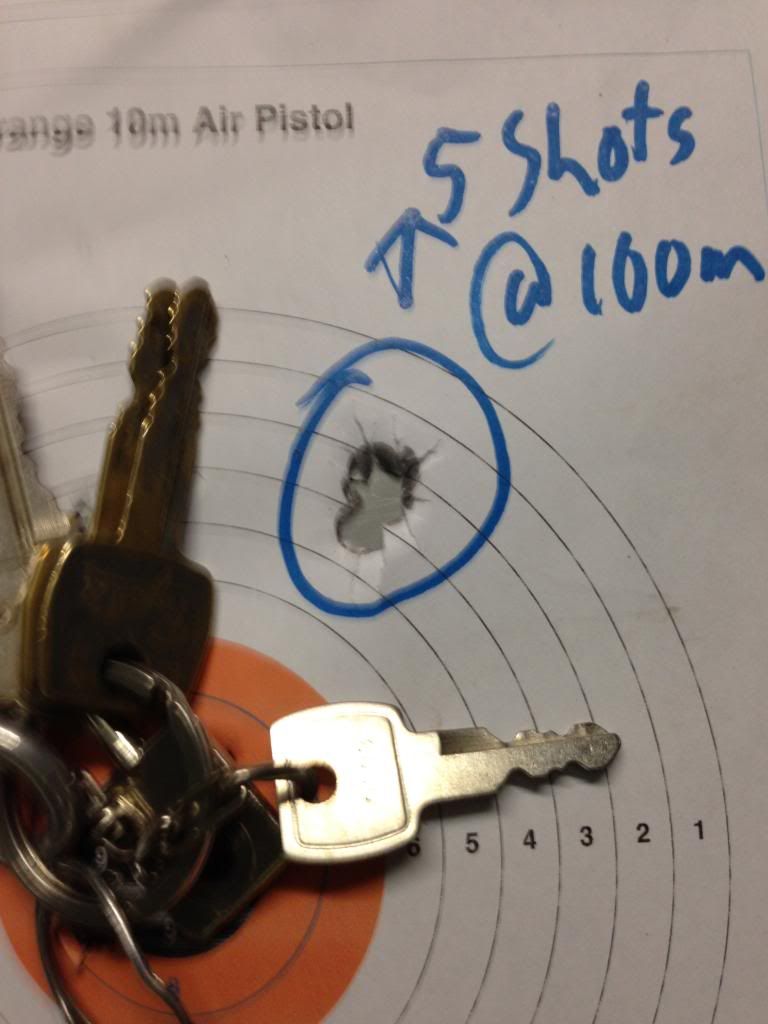

Then this at 100m, 5 shot.

So it seems to be working . I imagine the pattern on the muzzle would still look the same as my photo above that i posted earlier 😎

This is the rem with Lilya 28" barrel and 155 bergers , thrown with the charge master .

The gong was set up at 1030 m . Upper group was 9.7mills elevation. Lower group was 9.6 mills .

Then this at 100m, 5 shot.

So it seems to be working . I imagine the pattern on the muzzle would still look the same as my photo above that i posted earlier 😎

Return to “Equipment & Technical”

Who is online

Users browsing this forum: No registered users and 98 guests