284 Shehane Neck Turning Question

Moderator: Mod

-

Norm

- Posts: 837

- Joined: Fri Jul 23, 2010 10:21 pm

- Location: Gippsland, Victoria

- Has thanked: 6 times

- Been thanked: 11 times

Re: 284 Shehane Neck Turning Question

I also get variations with a K&M neck turner. I put this down to the mandrel heating up and trying to take too much brass off the neck in one hit.

Re: 284 Shehane Neck Turning Question

Hi Craig,

My setup with the k&m mandrel is to have an aluminium cooling heat sink and between each shell I sit the turning mandrel and holder back onto the heat sink. You can have a fan running on it or even (as I have done) have a c shaped block sitting in water or iced water to help cool.

If done correctly this keeps the mandrel at a very consistent temperature and gets very even turning. Also if you have the time - try and do the turn in two steps with the final trim only a skim. This not only keeps the final temperature heatup to a minimum but also minimizes the differences with the odd shell you have overturned.

My setup with the k&m mandrel is to have an aluminium cooling heat sink and between each shell I sit the turning mandrel and holder back onto the heat sink. You can have a fan running on it or even (as I have done) have a c shaped block sitting in water or iced water to help cool.

If done correctly this keeps the mandrel at a very consistent temperature and gets very even turning. Also if you have the time - try and do the turn in two steps with the final trim only a skim. This not only keeps the final temperature heatup to a minimum but also minimizes the differences with the odd shell you have overturned.

-

AlanF

- Posts: 7532

- Joined: Wed Jun 15, 2005 8:22 pm

- Location: Maffra, Vic

- Has thanked: 229 times

- Been thanked: 936 times

Re: 284 Shehane Neck Turning Question

Also, I have suspected some slippage of the cutter - the allen head clamp is not as effective as it could be in my opinion. What I do is after clamping it (as tightly as I dare without stripping threads etc.), I turn the cutter adjustment head clockwise until it firms up (not overdoing it). This can actually change the cutting depth slightly, so it may be a matter of trial and error to get it spot on, but it does seem to help keep the cutter in place. I've only ever used K & M. Are there other brands out there that work accurately without having to go to this amount of trouble? More particularly has anyone tried several brands of neck turner?

Re: 284 Shehane Neck Turning Question

Ive used the hornady one on 6 dasher cases. Wouldnt be using it for expecting long range consistency unless you tweak a few things. For starters the mandrels are undersized and you will need to get the next size up mandrel and skim it down on a lathe. Then the cutter itself doesnt cut all that clean so its a very slow process to make sure everything is neat and tidy. However going by Daves recommendation of a heat sink, I think results could become alot more consistent with that too.

-

ecomeat

- Posts: 1137

- Joined: Tue Jun 01, 2010 11:07 pm

- Location: Pimpama QLD

- Has thanked: 5 times

- Been thanked: 16 times

Re: 284 Shehane Neck Turning Question

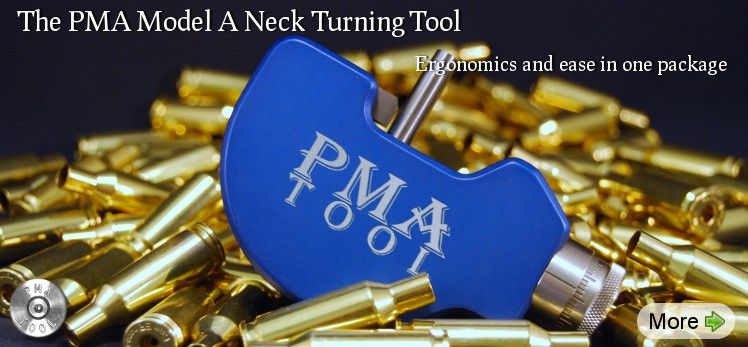

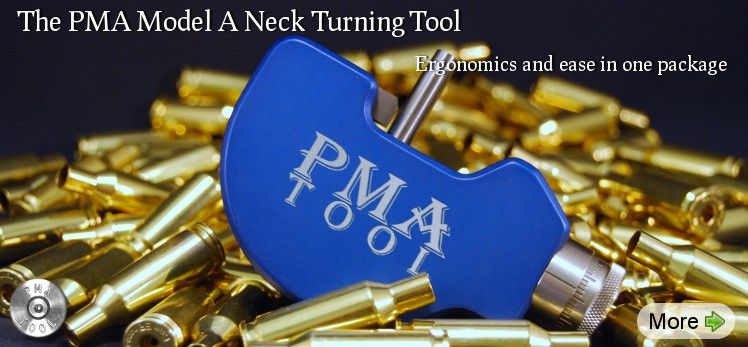

My last 500 or so 284 Win cases have been turned with my PMA Neck Turner.

PMA (Precision Made American Reloading Tools http://www.pmatool.com ) make some nifty reloading tools, and are the only ones that i know of who make a 35 deg Cutter, which is made for the 35 deg shoulder of the 284 cases.

Prior to this tool's arrival, i had used the K & M tool like everybody else, but using the 30 deg cutter on a 35 deg case shoulder doesnt make as much sense as using the "right" one, to me.

They are much easier to hold than the K & M and have fancy micrometer adjustment.

To keep any heat down whilst turning, i use those "Gel" freezer packs. and have one on my table to sit the PMA tool on, while i am spinning the case neck in steel wool as my final step, then removing the case and tightening the next one into my cordless-drill mounted case holder. Frozen works too, but deeply chilled is even better because the tool sits right down flat and gets maximum contact. You just need to keep rotating them and replacing with a "fresh" one, every 15 mins or so in summer.

The same deeply chilled (but not frozen) gel pads are a great way to cool a barrel down quickly between strings, if shooting something like 1000 yard Benchrest matches. They are thin enough and flexible enough that i can get one in under the objective lens, onto the chamber area of a thick barrel, to get the heat away from the throat.

PMA are a small company who are great to do business with, and regularly produce a short electronic Newsletter that i always enjoy reading. Pat Reagin who owns the company is right on top of very good customer service and makes you feel that he really appreciates your business. I cant recommend them highly enough.

Check out their Action Cleaning tools......bloody fantastic !

Tony

PMA (Precision Made American Reloading Tools http://www.pmatool.com ) make some nifty reloading tools, and are the only ones that i know of who make a 35 deg Cutter, which is made for the 35 deg shoulder of the 284 cases.

Prior to this tool's arrival, i had used the K & M tool like everybody else, but using the 30 deg cutter on a 35 deg case shoulder doesnt make as much sense as using the "right" one, to me.

They are much easier to hold than the K & M and have fancy micrometer adjustment.

To keep any heat down whilst turning, i use those "Gel" freezer packs. and have one on my table to sit the PMA tool on, while i am spinning the case neck in steel wool as my final step, then removing the case and tightening the next one into my cordless-drill mounted case holder. Frozen works too, but deeply chilled is even better because the tool sits right down flat and gets maximum contact. You just need to keep rotating them and replacing with a "fresh" one, every 15 mins or so in summer.

The same deeply chilled (but not frozen) gel pads are a great way to cool a barrel down quickly between strings, if shooting something like 1000 yard Benchrest matches. They are thin enough and flexible enough that i can get one in under the objective lens, onto the chamber area of a thick barrel, to get the heat away from the throat.

PMA are a small company who are great to do business with, and regularly produce a short electronic Newsletter that i always enjoy reading. Pat Reagin who owns the company is right on top of very good customer service and makes you feel that he really appreciates your business. I cant recommend them highly enough.

Check out their Action Cleaning tools......bloody fantastic !

Tony

Extreme accuracy and precision shooting at long range can be a very addictive pastime.

-

Craig McGowan

- Posts: 191

- Joined: Fri Jan 11, 2013 11:10 pm

- Location: Brisbane

- Been thanked: 29 times

- Contact:

Re: 284 Shehane Neck Turning Question

I tried all the suggestions. While I did notice a large improvement in the overall consistency of the cut for the diameter of the case, I did still however have cases that cut below and on the odd occasion above the required thickness.

Maybe I am expecting to much, but measuring 4 spots around a random case will often show 3 readings with thickness measuring as required and 1 either above or below the required measurement. It is only out by 1/4 of a thou, but is this what you would expect within the limits of both the cutter and the measuring tools.

I have noticed that it is very easy to get inconsistent reading with the mitatoyo thickness tooling depending on how quick you are with winding it in.

Note to self. Next time order a no turn reamer.........

Maybe I am expecting to much, but measuring 4 spots around a random case will often show 3 readings with thickness measuring as required and 1 either above or below the required measurement. It is only out by 1/4 of a thou, but is this what you would expect within the limits of both the cutter and the measuring tools.

I have noticed that it is very easy to get inconsistent reading with the mitatoyo thickness tooling depending on how quick you are with winding it in.

Note to self. Next time order a no turn reamer.........

Last edited by Craig McGowan on Tue Nov 25, 2014 7:54 pm, edited 1 time in total.

-

Cameron Mc

- Posts: 1089

- Joined: Tue Jun 28, 2005 10:55 am

- Location: Darling Downs SE Qld

- Been thanked: 1 time

Re: 284 Shehane Neck Turning Question

Craig, I feel your results are fine.

On the subject of measuring, that is an art in itself once you start measuring very small differences. That is 5/10 thousanths and less.

I have found it to be like primer seating with "feel" for consistancy. Practice makes perfect.

Cam

On the subject of measuring, that is an art in itself once you start measuring very small differences. That is 5/10 thousanths and less.

I have found it to be like primer seating with "feel" for consistancy. Practice makes perfect.

Cam

-

ecomeat

- Posts: 1137

- Joined: Tue Jun 01, 2010 11:07 pm

- Location: Pimpama QLD

- Has thanked: 5 times

- Been thanked: 16 times

Re: 284 Shehane Neck Turning Question

Craig McGowan wrote:Note to self. Next time order a no turn reamer.........

Craig, I know a bloke in Brisbane with a No Turn straight 284 Win reamer for sale

With those Mititoyo neck thickness tools, I find that if I wind in slowly and gently enough to register right on Zero just closing on itself with no case ,repeating that 3 or 4 times, and then try and repeat that very gentle, soft closing onto a case, then I get a lot more consistent readings where I need it.

Extreme accuracy and precision shooting at long range can be a very addictive pastime.

-

aaronraad

- Posts: 573

- Joined: Wed Aug 08, 2012 3:43 pm

- Location: Brisbane, Australia

- Has thanked: 3 times

- Contact:

Re: 284 Shehane Neck Turning Question

Anybody tried using lubricant to cool the tool? Keeping the tool sharp will also increase consistency, reduces friction/heat etc.

I see Varmint Al's comments on Hot Tool about 1/4 of way down the page on neck turning - http://www.varmintal.com/arelo.htm

Here is a link on cutting lubricants, use your "find" function in your browser to locate "brass"; I've actually got paraffin oil, but what the heck is "lard oil", sounds like something my grandmother use to cook everything with? - https://archive.org/stream/cuttinglubricant00newyrich/cuttinglubricant00newyrich_djvu.txt

I see Varmint Al's comments on Hot Tool about 1/4 of way down the page on neck turning - http://www.varmintal.com/arelo.htm

Here is a link on cutting lubricants, use your "find" function in your browser to locate "brass"; I've actually got paraffin oil, but what the heck is "lard oil", sounds like something my grandmother use to cook everything with? - https://archive.org/stream/cuttinglubricant00newyrich/cuttinglubricant00newyrich_djvu.txt

Be careful what you aim for, you might hit it! Antipodean Industrial - Home of the G7L projectiles

-

williada

- Posts: 969

- Joined: Wed Jul 22, 2009 12:37 am

- Has thanked: 263 times

- Been thanked: 422 times

Re: 284 Shehane Neck Turning Question

Aaron the best lard oil was made from pig fat. Don't waste that stuff dripping off your bacon. Harry Pope made the finest barrels using it as a lubricant. The downside is that it goes off and you can get infections.  David.

David.

-

Cameron Mc

- Posts: 1089

- Joined: Tue Jun 28, 2005 10:55 am

- Location: Darling Downs SE Qld

- Been thanked: 1 time

Re: 284 Shehane Neck Turning Question

I use Lanolin grease for neck turning. Brilliant.

It's good for the skin too

It's good for the skin too

Re: 284 Shehane Neck Turning Question

Craig- if you would like Im willing to rent my 284 shehane no turn reamer. 318nk and 220 freebore.

-

KHGS

- Posts: 950

- Joined: Thu Oct 20, 2005 12:46 am

- Location: Cowra NSW

- Has thanked: 776 times

- Been thanked: 537 times

Re: 284 Shehane Neck Turning Question

Cameron Mc wrote:I use Lanolin grease for neck turning. Brilliant.

It's good for the skin too

Imperial sizing wax is good too.

I do not turn in the conventional manner, my neck turner is about a ton in weight & 5 feet long

Keith H.

-

RDavies

- Posts: 2336

- Joined: Sun Feb 12, 2006 7:23 pm

- Location: Singleton NSW

- Has thanked: 715 times

- Been thanked: 760 times

Re: 284 Shehane Neck Turning Question

I like the 21st Century Shooting kits. The carbide cutters come in various different angles, and have the right radius. The mandrels are Titanium Nitride coated. Adjustments are very easy and precise. I found the expander mandrels are a good size match with the turning arbor to give the right case fit, not too tight like the Sinclairs mandrels. The owner of 21st Century Shooting, John is a good bloke and F class shooter.

http://www.21stcenturyshooting.com/Neck ... ol_Kit.php

http://www.21stcenturyshooting.com/Neck ... ol_Kit.php

Re: 284 Shehane Neck Turning Question

KHGS wrote:Cameron Mc wrote:I use Lanolin grease for neck turning. Brilliant.

It's good for the skin too

Imperial sizing wax is good too.

I do not turn in the conventional manner, my neck turner is about a ton in weight & 5 feet longsorry couldn't resist.

Keith H.

I agree with both of keiths points. I use the k&m turner with carbide and i run it at 300+ rpm and had no major concentricity issues doing it like that.