Rick there are few general principles to consider before we tackle your groups.

Firstly, the Magnetospeed adds ½ a pond of weight to your muzzle and distorts a group if subsequent groups are fired without it. There are two key reasons: (A) It requires about 4 ounces muzzle weight to counter torque on a .223 at your velocity and twist rate with an 80 grain projectile. The Magnetospeed is double that and generally groups tend to be better with one on, because the torque is largely taken out of the equation as it effects recoil for bag handling, reflected vibrations travelling backward and forward along the barrel prior to bullet exit and barrel lift for its compensation profile. So the muzzle weight is a damper. (B) On the other hand, assuming the groups were tight, you need to consider by way of fine tuning at what angle projectiles exit the barrel in terms of their compensation profile. Dealing with this aspect may only require a couple of grams to make significant change in launch angle or a ¼ of a turn of a tuner. The point I make is the application of weight at the muzzle has three distinct roles.

Secondly, it is the barrel length in terms of it harmonics like the slat on an xylophone that if it was to give the sweetest note it will give the tightest nodal group then the barrel length has to be right, and for the node to operate effectively it is velocity dependent. That means using your best reloads to keep spreads down to match that barrel length.

Let’s hone in on the neck tension. It’s one of the last things I do and it is only remedial to subtly change the group shape to make groups less wind sensitive after I have sorted the charge and seating depth and assuming I have other key tune factors sorted as some people have been following. It is the other key tune factors which have more impact on the velocity, hence bore-time and launch angle than seating tension.

Greater seating tension may improve burn efficiency if you are not jammed into the lands and you require a free flight to modify exit timing. But too much and you can distort the alignment in the case and a bullet started off centre will continue off centre because the projectile is malleable and will increase its external yaw as a consequence of its internal yaw.

What many do, is anneal their cases to sort friction variations or turn or trim their cases and have the correct neck clearance so carbon does not build up. Get that right and best neck tension is easier to detect. You need to try three different neck tensions for better comparison.

The key to testing is to get the order of magnitude of each right, then alter one variable at a time to refine things. For statistical significance the test should have 30 minimum samples if used in isolation if a true correlation is to be made.

There is a general assumption that a case should have a high powder density to burn efficiently. So the selection of the right powder is critical as is a matched primer. Typical ignition problems result in vertical groups. If that is right a good starting point is about .001” neck tension for jammed projectiles and .002” neck tension for free-flighted projectiles.

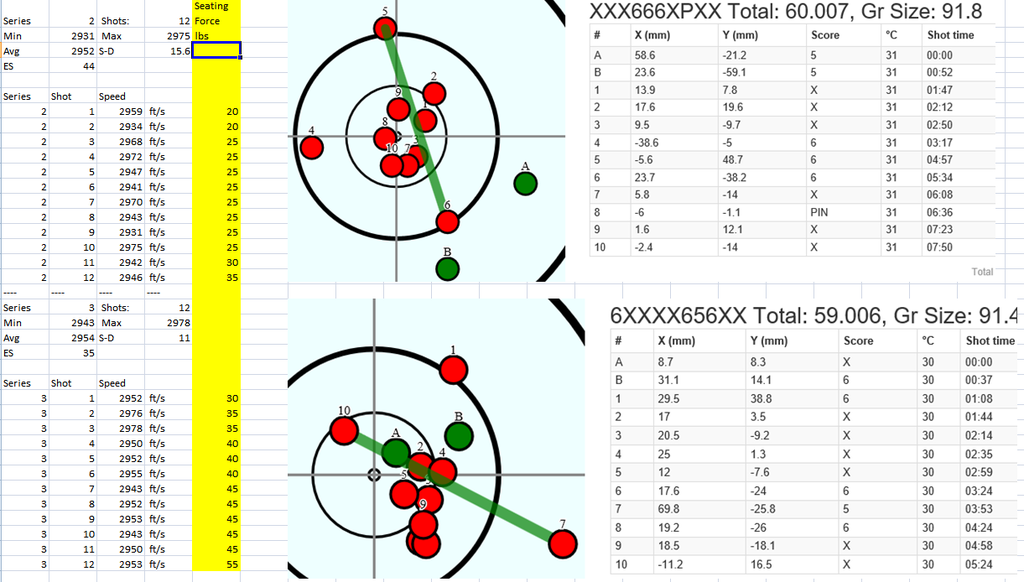

If we look at your groups below Rick, I think your groups in the first instance require more powder before you can see the subtleties of tune. I’m running 25.4 of 2208 in an old seasoned .223 barrel having carefully built it up now that its colder. Your loads should be seasonal.

Your groups are demonstrating a changed group shape due to better ignition but the vertical trend is still there nonetheless. This requires more charge before we even consider an appropriate compensation profile which is illusory due to Magnetospeed weight. If you are going to use a Magnetospeed, make a false weight to compensate for it when the Magneto speed is off your barrel. I like Malcolm's observation. Hope this helps Rick. David.

PS Thanks Jason, hope its more a help than a hindrance to fast track a few and I never stop learning either.